Dragflow Submersible Dredging Systems for Deepwater Applications

Dredging activities have been expanding their horizons with the increasing need for equipment that can pump highly specific gravity slurry and is suitable for deepwater dredging. Dragflow dredging systems are a proven technology in both fields, combining experience with intensive research and development.

Submersible dredge pumps for harsh conditions

Dragflow submersible dredge pumps have been designed and built to work especially in harsh conditions where generally normal pumps cannot operate. Our advanced design, which includes agitators, hydraulic cutters and pressure compensation of all equipment, allows for high-efficiency dredging, even in deep sea conditions.

The Dragflow agitator enables our pumps to rise and convey liquids and mixtures such as mud, slime, silt, sand and gravel with sizes up to 120mm.

Our pumps can work in very harsh and demanding conditions thanks to the special materials that are used to construct them. The agitator, impeller, and lower and upper wear plate are made of cast iron, including 30% chrome. This means they have a hardness of about 600HB / 650HB and, as a consequence, an incomparable abrasion resistance.

Heavy-duty submersible dredging pumps

Heavy-duty submersible pumps with agitators are available either in hydraulic or electric versions:

- Electric version power output: from 3.7kW up to 110kW

- Hydraulic version power output: from 9kW up to 300kW

Pumps can be equipped with hydraulic cutters which, coupled with the agitator, stir up the solids settled on the bottom in order to be easily pumped out, creating a homogeneous mixture with a higher percentage of solids and achieving a higher efficiency.

Hydraulic pumps and cutters are also specifically designed to be directly mounted and driven by a hydraulic excavator. This solution allows for incredibly short start-up operations and great flexibility in the use of the dredging equipment, without the need of any other power supply.

Mine tailings dredging

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an ore. The disposal of mine tailings is an important environmental issue for any mine during the project’s life. Mines usually have a disposal facility, which quite often takes the form of a dam or pond where Dragflow dredge systems can be used to extract the tailings in order to recover the capacity and further process the sediments.

Oil sands tailings, in particular, are a mixture of water, clay, sand and residual hydrocarbons produced during the mine extraction process. There, the heaviest material settles to the bottom, separating from the top layer of water, which can be recycled. The middle layer, known as mature fine tailings (MFT), could take centuries to solidify. Dragflow dredging systems are a reliable solution to getting the MFT out of the pond and processing it into a soil-like deposit suitable for reclaiming.

Heavy-duty pumps for contaminated sediments

Heavy-duty submersible pump applications in pollution control include: dams cleaning; refineries; ports cleaning; maintenance departments in almost all industrial applications; local environmental offices; city hall environmental departments; and mine tailings management.

Heavy-duty submersible pump systems

Heavy-duty submersible pump applications in dredging include the removal of sand and silt during piling / drilling activities; sand and gravel extraction; dredging of harbours and dams up to 300m depth and 120mm cross-section; dredging of contaminated sediments; and pumping bentonite slurries.

Dragflow can provide complete dredging systems, which include a hydraulic power pack specifically designed for the long hydraulic lines and harsh conditions typically connected with deep sea and offshore projects. All power packs can be wirelessly remote controlled for the convenience of operators during dredging activities.

Modular and transportable dredgers

Dragflow leads the field with the innovative design of systems that can improve productivity, minimise downtime and allow high working depth. Our products are well-known for pumping large quantities of solids with the agitator and the cutters, which put in suspension the material settled at the bottom. Dragflow dredges can work in deeper waters than any other dredge and deliver a higher quantity of dry tons per hour.

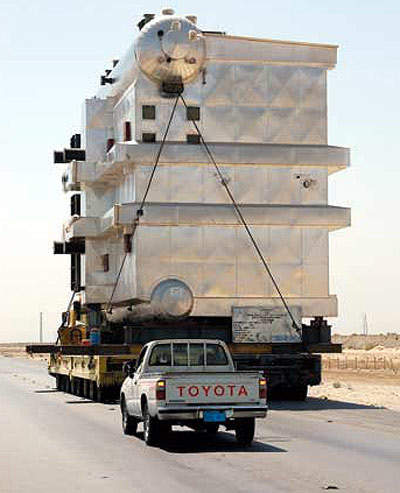

All Dragflow dredges are designed and manufactured in modular and transportable units. The use of simple components means low cost and ease of maintenance, simplicity to repair possible breakdowns, and less expensive spare parts.

Tailor-made dredging systems

As a result of the flexibility of our equipment and modularity of its components, Dragflow can manufacture different types of dredges to comply with different client requests. On demand, we can supply dredges in accordance to the rules of the Italian Naval Registration (RINA).

Dragflow dredges can be remote controlled in order to minimise labour and maximise the production of solids at the set flow rate.

Products and Services

Video

Related Projects

Suncor Project Voyageur, Fort McMurray, Alberta

Al Khaleej Gas – Phase Two (AKG-2) Project

Haradh

Qatif-Abu Sa’fah

Athabasca Oil Sands Project, Alberta

Press Release

Dragflow chooses to soften the environmental impact with advanced technologies for dredging optimisation and naturalistic protection.

Read moreA new trend of deep sea and high depth dredging and exploration is emerging in the dredging market. Deep sea exploration represents both a development possibility, and a huge technical challenge, where critical hyperbaric conditions, remote control and maintenance amends play an important role.

Read moreRegional Offices

Via Spagna 13 Villafranca

Verona

37069

Other

Italy